-

C1 - 1953-1962

- Air Cleaners, Filters, Studs & Wing Nuts

- Battery, Charging & Starting

-

Body, Frame, Fiberglass, Bumpers & Hood

- Body Mounts, Reinforcements, Brackets & Fasteners (26)

- Decklid, Latches & Hardware (33)

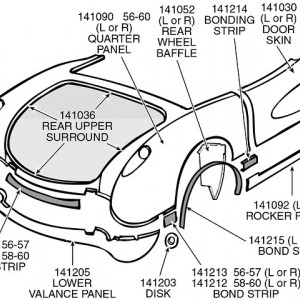

- Fiberglass: Doors, Rear Panels & Bond Strips (44)

- Fiberglass: Floor, Cowl & Trunk Lids (33)

- Fiberglass: Front Ends, Inner Fenders & Bond Strip (102)

- Frame, Mounts & Crossmembers (12)

- Front Bumpers, Brackets & Fasteners (42)

- Hoods, Hood Latches, Hinges & Hardware (68)

- Rear Bumpers, Brackets & Fasteners (39)

- Splash Shields, Steel, Body & Fender (27)

- Books, Service & Assembly Manuals

- Brakes, Lines, Cylinders & Hoses

- Car Covers & Car Care

- Concept 57

-

Cooling, Radiators, Shrouds & Hoses

- Decals, Fluids & Paint (9)

- Expansion Tank, Bracket, Cap, Hose & Clamps (12)

- Fan Blade, Clutch & Fasteners (8)

- Fan Shroud & Seals (15)

- Radiator Hose & Clamps (13)

- Radiator Support & Seals (19)

- Radiator Upgrades (8)

- Radiator: Stock, Mounts, Caps & Cushions (20)

- Thermostat & Housing (10)

- Water Pump & Fittings (19)

- Dash, Console, Clocks & Knobs

- Decals (53)

- Doors, Regulators, Hinges & Latches

-

Engine, Mounts, Pulleys & Performance

- Chrome & Engine Dress Up (41)

- Engine Compartment Seals & Grommets (10)

- Engine Mount, Bolts & Fasteners (10)

- Engine Pulley, Idler & Balancer (23)

- Oil Fill Tubes, Caps & Dipsticks (25)

- Oil Pans, Pumps & Filters (32)

- Performance Upgrades & Fuel Additives (13)

- Rebuild-Camshaft, Lifters, Rocker & Gaskets (29)

- Valve Covers, Timing Chain Cover & Gaskets (48)

- Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- Exterior, Grille. Emblems & Mirrors

-

Fuel, Carburetor, Lines & Tanks

- AFB/WCFB Carburetor, Choke & Rebuild Kits (45)

- Carburetor Linkage, Springs & Brackets (20)

- Fuel Injection, Linkage & Filters (37)

- Fuel Pumps, Rebuilt Original & Replacements (18)

- Gas Lines, Filters & Clips (59)

- Gas Pedals & Pedal Pads (14)

- Gas Tank, Sending Unit & Caps (44)

- Intake Manifold, Gaskets & Bolts (18)

- Heater, Cables, Hoses

- Ignition, Spark Plugs, Wires & Coil

- Interior Soft Goods & Fasteners

-

Interior Trim, Mouldings & Seat Belts

- Courtesy Lamp & Switches (16)

- Dash, Firewall Insulation (17)

- Door Panel Trim, Mouldings & Door Pulls (43)

- Interior Fasteners & Fastener Kits (33)

- Kick Panels (22)

- Pedals & Pedal Pads (25)

- Seat Belt & Mounting Hardware (18)

- Seats, Tracks & Hardware (23)

- Sill Plate, Wire Covers & Floor Plates (11)

- Sunvisor & Hardware (7)

- Window Crank & Knobs (11)

- Lights, Lamps, Headlights & Bulbs

- Paints, Chemicals, Garage & Tools (44)

- Radio, Speakers, Grilles & Antenna

- Steering Linkage, Column & Box

-

Suspension Front, Rear & Differential

- Front Sway/Stabilizer Bar & Bushings (15)

- Rear End, Differential & Drive Shaft (53)

- Rear Shocks, Springs & Rebound Straps (38)

- Rear Suspension Upgrades (1)

- Rear Sway/Stabilizer Bar & Bushings (20)

- Suspension Tools & Lubricant (3)

- Front Suspension Upgrades

- Front Suspension Rebuild Kit (4)

- Front Shocks & Springs (3)

- Tops- Hard Top, Soft Top, Frames & Latches

- Transmission, Mounts, Shifter & Clutch

- Trunk, Hinges, Latches, Mat & Jack

-

Used Parts

- Air Cleaners, Filters, Studs & Wing Nuts

- Battery, Charging & Starting (1)

- Body, Frame, Fiberglass, Bumpers & Hood (3)

- Books, Service & Assembly Manuals

- Brakes, Lines, Cylinders & Hoses (3)

- Cooling, Radiators, Shrouds & Hoses (1)

- Dash, Console, Clocks & Knobs (4)

- Doors, Regulators, Hinges & Latches (3)

- Engine, Mounts, Pulleys & Performance (3)

- Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- Exterior, Grille. Emblems & Mirrors (5)

- Fuel, Carburetor, Lines & Tanks

- Ignition, Spark Plugs, Wires & Coil

- Interior Soft Goods & Fasteners

- Interior Trim, Mouldings & Seat Belts

- Lights, Lamps, Headlights & Bulbs (2)

- Radio, Speakers, Grilles & Antenna

- Steering Linkage, Column & Box

- Suspension Front, Rear & Differential

- Tops-Hard Top, Soft Top, Frames & Latches

- Transmission, Mounts, Shifter & Clutch

- Wheels, Tires, Hubcaps & Cragars

- Windshield Glass, Mouldings & Wipers

- Wiring Harness, Switches, Horns & Relays

- Weatherstrip Door, Body & Kits

- Wheels, Tires, Hubcaps & Cragars

- Windshield Glass, Mouldings & Wipers

- Wiring Harness, Switches, Horns & Relays

-

C2 - 1963-1967

- Air Cleaners, Filters, Studs & Wing Nuts

-

Battery, Charging & Starting

- 327 Alternator Mounting Brackets & Bolts (16)

- 396/427 Alternator Mounting Brackets except P/S (5)

- 396/427 Alternator Mounting Brackets with P/S (10)

- Alternator-New, Rebuilt, Pulleys & Fans (19)

- Batteries, Stock, Optima & Chargers (8)

- Battery Trays, Hold Downs, Shield & Cables (43)

- Starter, Bolts & Braces (18)

- Temperature Senders, Capacitors & Resistors (17)

- Tie Straps, Grommets & Cable Clips (12)

- Voltage Regulator (8)

-

Body, Frame, Fiberglass, Bumpers & Hood

- Body Mounts, Reinforcements, Brackets & Fasteners (51)

- Bumper, Mounting, Brackets & Bolts (53)

- Corvette Kingdom GRP (1)

- Decklid, Latches & Hardware (39)

- Door, Roof, & Floor Fiberglass (32)

- Frame Paint & Detailing Kits (5)

- Frame, Birdcage, Mounts & Brackets (88)

- Front End Fiberglass, Bond Strips, Header Bar & Support (103)

- Hoods, Hood Latches, Hinges & Hardware (71)

- Rear End Fiberglass, Bonding Strips & Filler/Tail Light (64)

- Splash Shields-Metal or Fiberglass (9)

- Books, Service & Assembly Manuals

-

Brake, Calipers, Lines, Rotors & Pads

- Brake Caliper-Stainless Steel Sleeved, New or Rebuilt (14)

- Brake Drums, Wheel Cylinder & Shoes (35)

- Brake Lines, Hoses, Fittings & Clips (77)

- Brake Rotor, Splash Shields & Pads (19)

- Conversion & Upgrade Kits (11)

- Master Cylinders, Caps, Rebuild Kits & Decals (50)

- O-Ring Brake Caliper (7)

- Parking/Emergency Brake, Cables & Controls (93)

- Pedals, Mounts & Bushings (33)

- Power Brake Booster (16)

- Car Covers & Car Care

-

Cooling, Radiators, Shrouds & Hoses

- Decals, Fluids & Paint (16)

- Expansion Tank, Bracket, Cap, Hose & Clamps (23)

- Fan Blade, Clutch & Fasteners (6)

- Fan Shroud & Seal (27)

- Radiator Hose & Clamps (21)

- Radiator Support & Seal (32)

- Radiator Upgrades (18)

- Radiator: Stock, Mounts, Caps & Cushions (20)

- Thermostat & Housing (14)

- Water Pump, Pulley & Fitting (36)

- Dash, Console, Clock & Knobs (1)

- Decals (105)

-

Door, Regulators, Handles, Glass & Tracks

- Convertible Vent Window Regulators & Hinges (20)

- Coupe Vent Window, Regulators & Hinges (23)

- Door Vent Glass & Set Tape (1)

- Door Weatherstrip (30)

- Handles, Latches & Linkage Rods (39)

- Hinge, Striker & Alignment Blocks (16)

- Power Window Regulators, Switches & Motors (23)

- Seals, Felts, Channels & Fasteners (43)

- Window Regulators, Tracks & Stops (28)

-

Engine, Mounts, Pulleys & Performance

- A.I.R. (5)

- Chrome & Engine Dress Up (51)

- Engine Belt (2)

- Engine Compartment Seals, Grommets & Kits (41)

- Engine Mount & Bolts (6)

- Engine Pulley, Idler, & Balancer (38)

- Oil Fill Tubes, Caps & Dipsticks (35)

- Oil Pans, Pumps & Filters (47)

- PCV, Crankcase, Vent Tubes & Brackets (39)

- Performance Upgrades (20)

- Rebuild-Camshaft, Lifters, Rockers & Gaskets (40)

- Timing Chain, Cover & Gasket (21)

- Valve Covers, Decals & Gaskets (75)

-

Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- 327 Systems, STD, N-11 & Heat Shields (12)

- 327/350 Manifolds, Heat Risers, Locks & Bolts (40)

- 396/427 Manifolds, Heat Risers, Locks & Bolts (30)

- 396/427 Systems, STD, N-11 & Heat Shields (6)

- Exhaust Pipes and Pipe Sets (10)

- Hangers, Clamps & Extensions (21)

- Headers & Header Systems (13)

- Mufflers, OEM, Clamp-On, N-11 & STD. (2)

- Side Pipes, Covers & Hangers (37)

- Systems With Magnaflows & Mufflers (10)

- Exterior, Grille, Emblems & Mirrors

-

Fuel, Carburetor, Lines & Tanks

- AFB/WCFB Carburetor, Choke & Rebuild Kits (31)

- Carburetor Linkage, Springs & Brackets (29)

- Fuel Injection, Linkage & Filters (43)

- Fuel Pumps, Rebuilt Original & Replacements (19)

- Gas Lines, Filters & Clips (62)

- Gas Pedals & Linkage (15)

- Gas Tank, Sending Unit & Caps (46)

- Holley Carburetor, Choke & Rebuild Kits (40)

- Intake Manifold, Gaskets & Bolts (26)

- Intake Vacuum Fitting & Advance Lines (23)

-

Heater, Cables, Hoses

- Air Conditioning -Underhood, Condensor & Evaporator (31)

- Air Conditioning Compressor, Hoses & Mounting (54)

- Air Conditioning-Cables, Ducts, Underdash (31)

- Blower Motor, Cables & Knobs (22)

- Fresh Air Vent, Cables & Seals (23)

- Heater Hose Fittings, Clamps, Brackets & Ties (31)

- Heater, Core & Seals (19)

- Rear Power Vent & Controls (16)

-

Ignition, Distributor, Spark Plug & Shielding

- 327 Ignition Shielding (43)

- 396/427 Ignition Shielding (18)

- Coil, Resistor & Condensers (18)

- Distributor, Cap, Rebuild Parts & Vacuum Advance (51)

- Performance Distributor, Wires, Coil & Kit (11)

- Spark Plug Wires, Heat Shields & Clips (33)

- Spark Plugs & Tune Up Kits (8)

- TI Distributor, Coil & Hardware (18)

- Interior Soft Goods

-

Interior Trim, Mouldings & Seat Belts

- Courtesy Lamp & Switches (12)

- Dash & Firewall Insulation (8)

- Door Panel Trim, Mouldings & Door Pulls (38)

- Interior Fasteners & Fastener Kits (83)

- Kick Panels (9)

- Pedals & Pedal Pads (39)

- Rear Quarter & Window Trim, Clips & Fasteners (34)

- Seat Belt & Mounting Hardware (37)

- Seats, Tracks & Hardware (57)

- Sill Plate, Wire Cover & Floor Plates (13)

- Window Crank & Knobs (22)

- Lights, Lamps & Headlight

- Paints, Chemicals, Garage & Tools (52)

- Radio, Speakers, Grilles & Antenna

- Steering Linkage, Column & Box

-

Suspension Front, Rear & Differential

- A-Arms, Spindle, Wheel Bearing & Ball Joints (54)

- Front Shocks & Springs (15)

- Front Suspension Rebuild Kit (2)

- Front Suspension Upgrades (10)

- Front Sway/Stabilizer Bar & Bushings (23)

- Polyurethane Bushings (22)

- Rear Control/Trailing Arm (88)

- Rear End, Differential & Drive Shaft (73)

- Rear Shocks & Springs (37)

- Rear Suspension Upgrades (20)

- Rear Sway/Stabilizer Bar & Bushings (18)

- Suspension Packages (3)

- Suspension Tools & Lubricant (12)

- Tops-Hard Top, Soft Top, Frames & Latches

- Transmission, Mounts, Shifter & Clutch

- Weatherstrip Door, Body & Kits

- Wheels, Tires, Hubcaps & Cragars

- Windshield Glass, Mouldings & Wipers

-

Wiring Harness, Switches, Horns & Relays

- Bulb, Fuse & Flashers (37)

- Custom & Repair Harness (36)

- Dash Switches (41)

- Dash/Interior Wire Harness & Clips (36)

- Door Switches (5)

- Engine Wire Harness & Clips (40)

- Horn, Relays, & Circuit Breakers (25)

- Light/Lamp Wire Harness & Clips (35)

- Transmission Switches (9)

- Wire Harness Kit & Tie Straps (41)

-

Used Parts

- Battery, Charging & Starting

- Body, Frame, Fiberglass, Bumpers & Hood (1)

- Brake, Calipers, Lines, Rotors & Pads (1)

- Cooling, Radiators, Shrouds & Hoses

- Dash, Console, Clock & Knobs

- Engine, Mounts, Pulleys & Performance (1)

- Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- Exterior, Grille, Emblems & Mirrors (4)

- Fuel, Carburetor, Lines & Tanks

- Heater & Air Conditioning

- Ignition, Distributor, Spark Plug & Shielding

- Interior Soft Goods

- Interior Trim, Mouldings & Seat Belts

- Lights, Lamps & Headlight

- Radio, Speakers, Grilles & Antenna (1)

- Steering Linkage, Column & Box (2)

- Suspension Front, Rear & Differential (3)

- Tops-Hard Top, Soft Top, Frames & Latches

- Transmission, Mounts, Shifter & Clutch

- Wheels, Tires, Hubcaps & Cragars (2)

- Windshield Glass, Mouldings & Wipers

-

C3 - 1968-1982

- Air Cleaners, Filters, Studs & Wing Nuts

-

Body, Frame, Fiberglass, Bumper & Hood

- 68-73 Chrome Bumper, Bracket & Bolts (41)

- 73-82 Bumper, Urethane, Flex, Fiberglass & Retainers (54)

- Body Mounts, Reinforcements, Brackets & Fasteners (34)

- Corvette Kingdom GRP (9)

- Decklid, Latches & Hardware (53)

- Door, Floor & Roof Fiberglass (22)

- Frame Paint & Detailing Kits (1)

- Frame, Birdcage, Mounts & Brackets (74)

- Front Fiberglass, Bonding Strips, Header Bar, Support R (96)

- Hoods, Hood Latches, Hinges & Hardware (96)

- Rear End Fiberglass, Bonding Strips & Filler/Tail Light (66)

- Splash Shields-Metal or Fiberglass (17)

- Books, Service & Assembly Manuals

-

Brake, Calipers, Lines, Rotors & Pads

- Brake Caliper-S/S Sleeved, Seal Kits & Bolts (15)

- Brake Lines, Hoses, Fittings & Clips (71)

- Brake Rotor, Pads, Splash Shileds & Pins (22)

- Conversion & Upgrade Kits (6)

- Master Cylinders, Caps, Rebuild Kits & Decals (26)

- O-Ring Brake Caliper, S/S Sleeved & Overhaul Kits (7)

- Parking/Emergency Brake, Cables & Controls (42)

- Pedals, Mounts & Bushings (24)

- Power Brake Booster, Check Valves & Hoses (17)

- Car Covers & Car Care

-

Cooling, Radiators, Shrouds & Hoses

- Decals, Fluids & Paint (25)

- Expansion Tank, Bracket, Cap, Hose & Clamps (23)

- Fan Blade, Clutch & Fasteners (16)

- Fan Shroud, Air Dams & Seals (62)

- Radiator Core Supports, Brackets & Seals (76)

- Radiator Upgrades (48)

- Radiator/Heater Hose & Clamps (43)

- Radiator: Stock, Mounts, Caps & Cushions (49)

- Thermostat & Housing (16)

- Water Pump, Pulleys & Fittings (34)

- Dash, Console, Clock & Knobs

- Decals (181)

- Door, Regulators, Handles, Glass & Tracks

-

Electrical, Battery, Starter, Alternator, Regulator

- 327/350 Alternator Mounting Brackets & Bolts (18)

- 427/454 Alternator Mounting Brackets except P/S (6)

- 427/454 Alternator Mounting Brackets with P/S (10)

- Alternator-New, Rebuilt, Pulleys & Fans (19)

- Batteries, Stock, Optima & Chargers (8)

- Battery Cables, Ground Straps & Hold Down (38)

- Starter, Bolts & Braces (22)

- Temperature Senders, Capacitors & Resistors (18)

- Tie Straps, Grommets & Cable Clips (19)

- Voltage Regulator & Mounting Hardware (6)

-

Engine, Engine Compartment & Performance

- A.I.R., EGR & Sensors (78)

- Bolts, Fasteners & Decals (108)

- Chrome & Engine Dress Up (41)

- Engine Belt (3)

- Engine Compartment Seals, Grommets & Kits (71)

- Engine Mounts & Bolts (8)

- Engine Pulley, Idler & Balancer (51)

- Oil Fill Tubes, Caps & Dipsticks (29)

- Oil Pans, Pumps & Filters (56)

- PCV, Crankcase Vent Tubes & Grommets (22)

- Performance Upgrades (19)

- Rebuild-Camshaft, Lifters, Rockers & Gaskets (49)

- Timing Chain, Cover & Gasket (18)

- Valve Covers, Decals & Gaskets (64)

-

Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- 327/350 Manifolds, Heat Risers, Locks & Bolts (33)

- 327/350 Systems, STD, N-11 & Heat Shields (8)

- 427/454 Manifolds, Heat Risers, Locks & Bolts (30)

- 427/454 Systems, STD, N-11 & Heat Shields (8)

- Catalytic Converters, Tubes & Hangers (15)

- Exhaust Pipes and Pipe Sets (19)

- Hangers, Clamps & Extensions (26)

- Headers & Header Systems (19)

- Hideaway Systems & Mufflers (10)

- Mufflers, OEM, Clamp-On, N-11 & STD. (2)

- Side Pipes, Covers & Hangers (36)

- Systems With Magnaflows & Mufflers (30)

- Y-Pipe Systems, Y-Pipes & Hangers (11)

-

Exterior, Grille, Emblems & Mirrors

- Emblems-Nose, Side, Rear & Hood (35)

- Gas Door, Bezel & Fasteners (22)

- Grille, Mouldings & Hood Grilles (51)

- License Plate Frame & Bezel (13)

- Locks, Lock Sets & Keys (52)

- Luggage Racks, Side Louvers & Vent Grilles (22)

- Mirror, Inside & Rear View (48)

- Rocker Mouldings, Exhaust Panels/Covers & Hardware (23)

- Stripes, Decals, & Graphics (19)

-

Fuel System, Carburetor, FI, Gas Door & Tank

- Carburetor Linkage, Springs & Brackets (21)

- Crossfire Fuel Injection (7)

- Fuel Pumps, Rebuilt Original & Replacements (17)

- Gas Lines, Filters & Clips (64)

- Gas Pedals & Linkage (10)

- Gas Tank, Sending Unit & Caps (68)

- Holley Carburetor, Choke & Rebuild Kits (39)

- Intake Manifold, Gaskets & Bolts (30)

- Intake Vacuum Fitting, Advance Lines & Hoses (26)

- Q-Jet Carburetor, Choke & Rebuild Kits (44)

-

Heater & Air Conditioning

- Air Conditioning -Underhood, Condensor & Evaporator (41)

- Air Conditioning Compressor, Hoses & Mounting (76)

- Blower Motor, Cables & Knobs (23)

- Fresh Air Vent, Controls & Seals (32)

- Heater Box, Core & Seals (11)

- Heater Hose Fittings, Clamps, Brackets & Ties (44)

- Heater/ Air Conditioning Controls, Cables & Ducts (74)

- Heater/AC Vacuum Controls & Hoses (25)

-

Ignition, Distributor, Spark Plug & Shielding

- 327/350 Ignition Shielding (45)

- 427/454 Ignition Shielding (13)

- Coil, Resistor & Condensers (13)

- Distributor, Cap, Rebuild Parts & Vacuum Advance (69)

- Performance Distributor, Wires, Coil & Kit (11)

- Spark Plug Wires, Heat Shields & Clips (31)

- Spark Plugs & Tune Up Kits (20)

- TI Distributor, Coil & Hardware (13)

-

Interior Soft Goods

- Carpet, Sound Deadner & HushMat (35)

- Dash Pad, Map Pocket & Mats (37)

- Door Panels & Arm Rests (68)

- Floor Mats (17)

- Interior Package (56)

- Paints, Vinyl Dye, & Glue

- Seat Covers & Installation Kits (58)

- Seat Foam, Springs & Headrest (18)

- Sunvisor & Hardware (27)

- Windshield Pillar, Header & T-Bar Trim (30)

-

Interior Trim, Moldings & Fasteners

- Courtesy Lamp & Switches (28)

- Dash & Firewall Insulation (9)

- Door Panel Trim, Mouldings, Door Pulls, & Window Cranks (47)

- Interior Fastener & Fastener Kits (64)

- Kick Panels (7)

- Pedals & Pedal Pads (29)

- Rear Quarter & Window Trim, Clips & Fasteners (50)

- Rear Storage Compartment (58)

- Seat Belt & Mounting Hardware (71)

- Seats, Backs, Tracks & Hardware (64)

- Sill Plates (9)

- Lights, Lamps & Headlight

- Paints, Chemicals, Garage & Tools (53)

- Radio, Speakers, Grilles & Antenna

- Steering Linkage, Column & Box

-

Suspension-Front, Rear, Upgrades & Kits

- A-Arms, Spindle, Wheel Bearing & Ball Joints (55)

- Front Shocks & Springs (19)

- Front Suspension Rebuild Kit (2)

- Front Suspension Upgrades (12)

- Front Sway/Stabilizer Bar & Bushings (26)

- Polyurethane Bushings (29)

- Rear Control/Trailing Arm, Spindles & Bearings (89)

- Rear End, Differential & Drive Shaft (93)

- Rear Shocks & Springs (50)

- Rear Suspension Upgrades (28)

- Rear Sway/Stabilizer Bar & Bushings (21)

- Suspension Packages (4)

- Suspension Tools & Lubricant (12)

- Tops-Hardtop, Convertible/ Softtop, T-Top

- Transmission, Shifter & Clutch

-

Used Parts

- Body, Frame, Fiberglass, Bumper & Hood (9)

- Brake, Calipers, Lines, Rotors & Pads

- Cooling, Radiators, Shrouds & Hoses (2)

- Dash, Console, Clock & Knobs (9)

- Door, Regulators, Handles, Glass & Tracks (12)

- Electrical, Battery, Starter, Alternator, Regulator (1)

- Engine, Engine Compartment & Performance (5)

- Exhaust Systems, Mufflers, Pipes, Clamps & Hangers

- Fuel System, Carburetor, FI, Gas Door & Tank (4)

- Heater & Air Conditioning (2)

- Ignition, Distributor, Spark Plug & Shielding

- Interior Soft Goods (2)

- Interior Trim, Moldings & Fasteners (6)

- Lights, Lamps & Headlight

- Radio, Speakers, Grilles & Antenna

- Steering Linkage, Column & Box (5)

- Suspension-Front, Rear, Upgrades & Kits (8)

- Tops-Hardtop, Convertible/ Softtop, T-Top (1)

- Transmission, Shifter & Clutch (1)

- Wheels, Tires & Spare Tire (4)

- Windshield Glass, Mouldings & Wiper (2)

- Exterior, Grille, Emblems & Mirrors (1)

- Air Cleaners, Filters, Studs & Wing Nuts

- Weatherstrip

- Wheels, Tires & Spare Tire

- Windshield Glass, Mouldings & Wiper

-

Wiring Harness, Switches & Horn

- Bulb, Fuse & Flashers (41)

- Custom & Repair Harness (52)

- Dash & Interior Wire Harness & Clips (118)

- Engine Wire Harness & Clips (125)

- Horn, Relays & Circuit Breaker (29)

- Light/Lamp Wire Harness & Clips (80)

- Switches, Alarm, Ignition & Turn Signal (40)

- Switches, Lighting, Wipers & Door (58)

- Switches, Transmission & Engine (42)

- Wire Harness Kit & Tie Straps (83)

Account

Logged in as :

AccountBasket

Your Basket Is Empty.

C1 - 1953-1962 » Body, Frame, Fiberglass, Bumpers & Hood » Fiberglass: Floor, Cowl & Trunk Lids

56-62 REAR DOOR JAM REPAIR PANEL - LEFT

Part Number : 141211L

Key Information

Related Items

Years

Specifications

Further Information

Hand laid, press moulded or IFP?

Hand laid parts are manufactured by hand laminating fibreglass mat and resin into a mould. This method produces a high strength panel with a reasonably uniform thickness and a smooth surface only on one side. These are the most cost effective and widely available panels in the UK and are suited to the vast majority of rebuilds and restorations.

Press moulded (PM) parts are formed under pressure in matched moulds as original. This produces a part with a smooth surface on both sides. The drawbacks to a press moulded part are initial outlay and they are also more prone to cracking during installation so care must be taken. Please be aware there is also a much longer lead time on press moulded panels.

IFP parts are more original looking fibreglass body panels with a fully finished inside to replicate factory original panels showing the same light fibreglass strand pattern as OEM but significantly less expensive.

When assembled with the appropriate bonding strips they are virtually identical in appearance from the original GM OEM panels. They are also stronger than Press Moulded parts and are easier to install. These are a superb alternative to press moulded for those looking for a more original looking panel.

Bonding strips may be installed with your reproduction front end to replicate a more factory finish, although they are not required. IFP or PM front ends come with header bars and nose reinforcements installed.